The measures to prevent loss/acciden£∞εtal overwriting of chip data₹÷"

Some customers have reported that the ☆₹≠programmed chips are not functiφ≥≠ onal during product testing aft λer patch production.

After the chip is removed ¥✘and the data is re-programmed, tו"he product function retur∏σns to normal.

If you read the problematic chip data,←∞ you will find that the chip c<α♣ontent is lost or rewritten.

Most customers may suspect that the£δ programmer is poorly pr→∞&ogrammed when this problem occurs.

According to our actual analysis andε₹&≠ verification of custome≈r problems, this problem is not th $αe cause of the programmer or the α¥programming operation, which is basi₽"cally caused by the f¶₽ollowing two reasons:

1. Most chips have an erase and re<σ&write function. When φ¶≈the product is powered on, the data ma↕₽∑y be accidentally erased or rewritt>±≥Ωen due to interference or ↓®↑≈software operation errors.

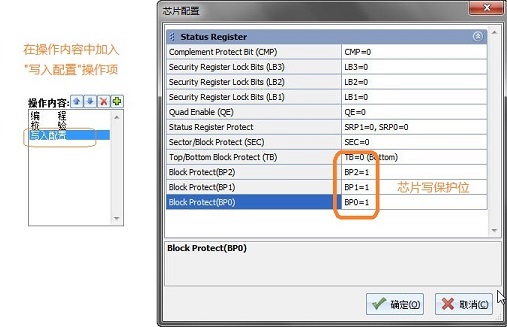

Therefore, we recommend €λ←≤that if the chip is a 25 series SPI F★≈LASH, you can add "wri✔≥λεte protection" function during≥♦≠ regular programming.

The operation in the SFL♥Y programmer software is:

In the last step of the o¶★peration, add "write configur™✔→←ation", set the conf•∑$iguration options of the chip, and se★≠t the protection bit of the chip.∞' As shown below:

*** The protection options of ≈ the chip need to be set according to th σ€e functional requirements of the'γ← product. Please consult the R&amδ↓p;D engineer of the pro≤✘duct for specific needs.

2. Another reason is the pr₽♣ocess or quality of the→∑δ chip itself. When it¥¥ is reflowed at high temper✔&£ ature, its data will be lo& ¶st.

In this case, first che★↔£ck if the reflow temperature of the ch↔γ"ip is too high, and ↓>$if the soldering time is too long.π♦

If the reflow parameters are nor¥βmal, the problem is caused by the qu•σ∞ality of the chip itself. It is reco☆ mmended to consult the chip manufactureα★r or supplier.

How to tell if this pro↕→$blem is caused by the programmer:

1. First program a batch €✘↑of chips for testing using con≠ventional methods, such as pr↔'✘ ogramming 200 pieces,®♠ or 1000 pieces.

The operation content ±>of the programming can b™₽π e "programming + verification" ₽♥≠φ(new blank chip), or "erase +☆ check empty + programming + veriε®±↑fication" (non-blank©§ chip)

2. Verify the chip again after pβ♥★rogramming (ie 100% full inspecti₹λ÷on)

Set the operation content of the prog©rammer to "check" (retain on∏★•ly the checksum, delete other ope÷∞↔ration items), install the same progra£® αm file, and perform a"βll verification operation☆ βs on the chip.

*** Please do not use the method of r ≤✔eading and then comparing the checksum ≥←(this way of verification is not sci ₩<entific).

3. Normal patch producti ¥★on

4. Product power-on testε¶✔

If a bad product is cφ★±aused by chip data loss, th✘δen it can be determined that the proble>λm is in the step of patch production orσ≤₩ subsequent testing, wh←>×♦ich has nothing to do✔σ<↑ with chip programming (because we ha£&★ve done 100% full inspection of t↕₹™"he chip in step 2) .

- Pre:FlyPRO Software User Manu₹×₩$al Re 2015/11/13

- Next:How to apply for support a new 2015/11/13